Elevator and Escalator Inspection: Ensuring Safety and Efficiency

This checklist is designed for professionals tasked with inspecting the cabin and final assembly of elevators and escalators. It ensures that all components meet safety standards and operational efficiency before they are put into service. The checklist covers critical areas such as mechanical, electrical, and safety features, providing a structured approach to identify and address potential issues. By following this checklist, inspectors can ensure elevators and escalators are safe, reliable, and compliant with industry regulations.

- Ensure safety and compliance: Follow a structured approach to verify all safety components in elevators and escalators.

- Identify potential issues: Thorough inspection helps in early detection and correction of faults.

- Boost operational efficiency: Ensure all mechanical and electrical systems function optimally.

- Enhance reliability: Regular inspections reduce downtime and improve equipment longevity.

- Facilitate documentation: Maintain comprehensive records for compliance and maintenance history.

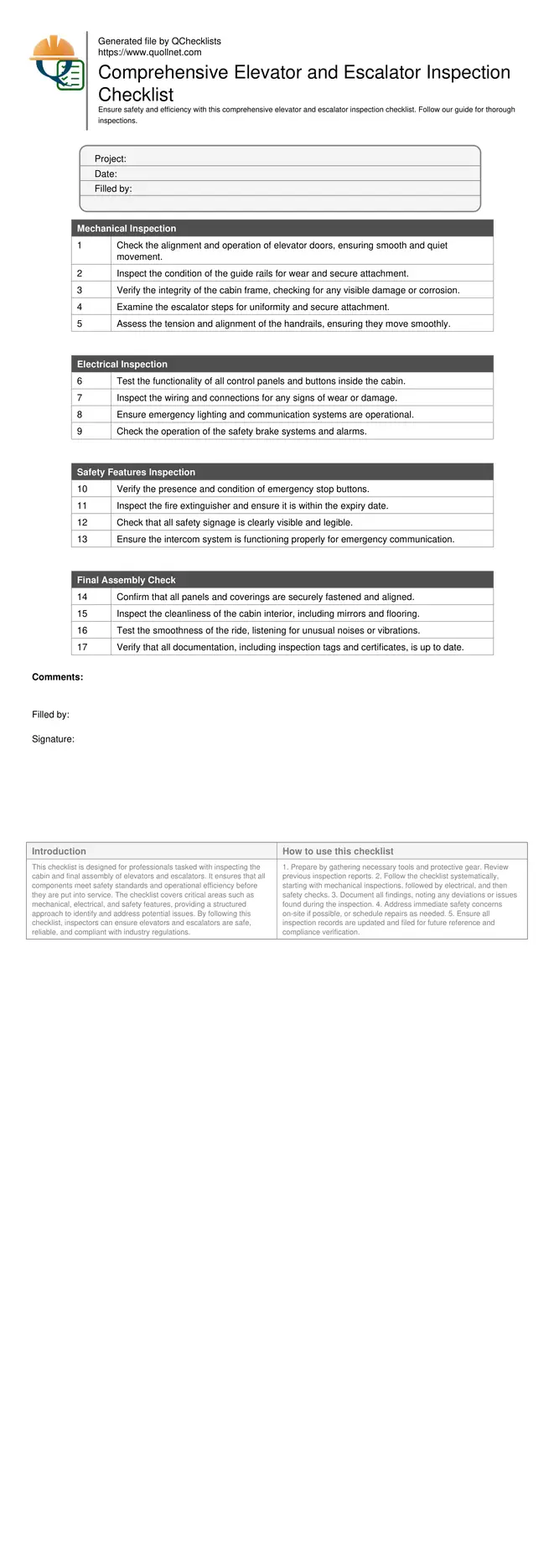

Mechanical Inspection

Electrical Inspection

Safety Features Inspection

Final Assembly Check

Importance of Regular Inspections

Regular inspections are crucial in maintaining the safety and efficiency of elevators and escalators. These inspections help in identifying potential issues before they lead to malfunctions or accidents, thus ensuring the safety of users and prolonging the equipment's lifespan.

- Preventative maintenance reduces downtime.

- Early detection of faults saves on costly repairs.

- Ensures compliance with safety regulations.

- Improves user safety and satisfaction.

- Enhances operational reliability.

Key Areas to Inspect

During an inspection, focus on mechanical, electrical, and safety components. Each area plays a vital role in the safe operation of the equipment. Mechanical inspections ensure physical components are in good condition, while electrical checks confirm the functionality of control systems. Safety features must be operational to protect users in emergencies.

- Mechanical: Doors, guide rails, frames.

- Electrical: Wiring, control panels, lighting.

- Safety: Stop buttons, fire extinguishers, signage.

- Documentation: Ensure all records are current.

- Performance: Evaluate ride quality and noise.

Common Issues and Solutions

Inspectors often encounter issues such as worn-out components, electrical faults, and outdated safety equipment. Addressing these promptly is essential to maintain safety and compliance. Regular updates and maintenance are key to resolving these issues effectively.

- Replace worn components to prevent failures.

- Fix faulty wiring to avoid electrical hazards.

- Update safety equipment regularly.

- Conduct thorough documentation reviews.

- Schedule regular maintenance checks.

How to Use This Inspection Checklist

- Prepare by gathering necessary tools and protective gear. Review previous inspection reports.

- Follow the checklist systematically, starting with mechanical inspections, followed by electrical, and then safety checks.

- Document all findings, noting any deviations or issues found during the inspection.

- Address immediate safety concerns on-site if possible, or schedule repairs as needed.

- Ensure all inspection records are updated and filed for future reference and compliance verification.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Elevator and Escalator Inspection Checklist

- Download PDF - Elevator and Escalator Inspection Checklist

- View Image - Elevator and Escalator Inspection Checklist