Waterproofing Membrane Inspection Checklist

This checklist is designed to guide professionals through the detailed inspection process of waterproofing membrane applications and their protection. Ensuring the correct application and maintenance of waterproofing membranes is crucial for the longevity and performance of any construction project. This checklist provides a step-by-step guide to verify that waterproofing standards are met, offering peace of mind and preventing costly repairs due to moisture infiltration.

- Ensure compliance with industry standards for waterproofing membrane applications, minimizing the risk of structural damage.

- Identify key inspection points during and after membrane application to ensure quality and performance.

- Protect your investment by preventing moisture-related issues with a thorough, systematic inspection process.

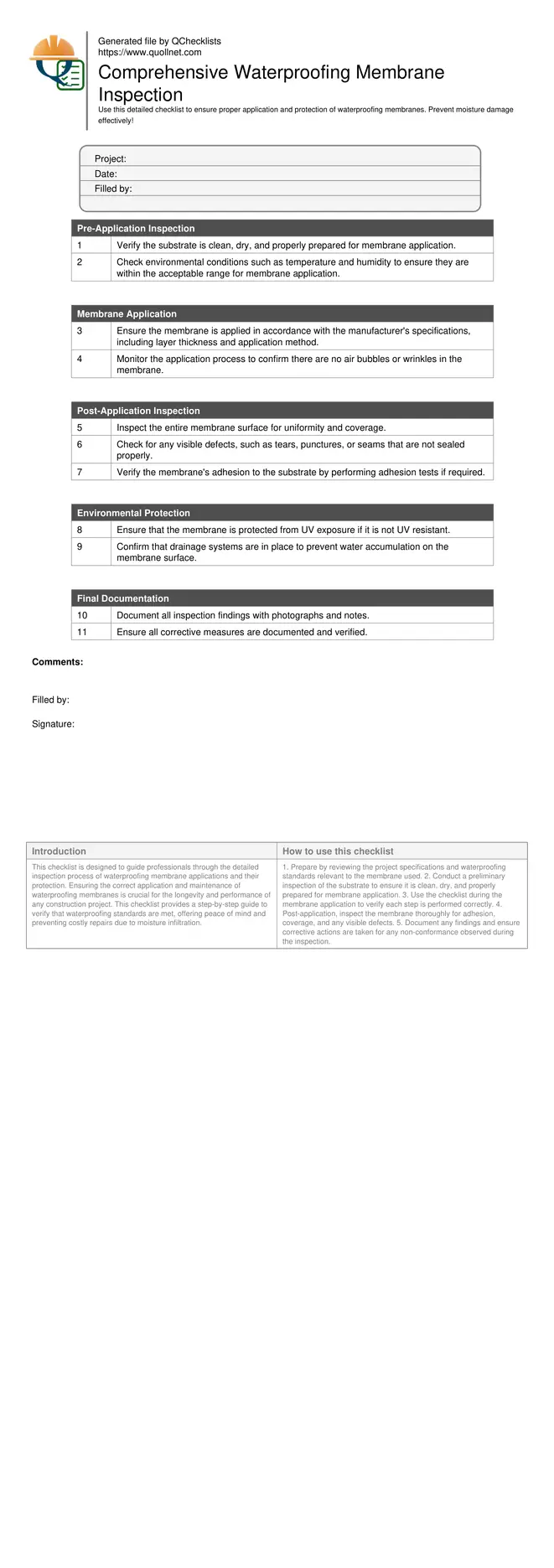

Pre-Application Inspection

Membrane Application

Post-Application Inspection

Environmental Protection

Final Documentation

Understanding Waterproofing Membranes

Waterproofing membranes are essential for protecting structures from water infiltration. They can be applied as liquid coatings, sheets, or sprayed materials. The choice of membrane depends on the application area, environmental conditions, and substrate type. Understanding these factors is crucial to conducting a thorough inspection.

- Types include sheet, liquid applied, and spray membranes.

- Selection depends on environmental and substrate conditions.

- Proper installation is key to membrane effectiveness.

Importance of Inspection

Inspections ensure that waterproofing membranes are installed correctly and remain intact over time. This process includes checking for proper adhesion, coverage, and the presence of any defects or damage. Regular inspections help in identifying potential issues before they lead to significant damage.

- Verify adhesion and coverage of the membrane.

- Detect and address defects or damages early.

- Ensure compliance with installation guidelines.

Common Inspection Challenges

Inspecting waterproofing membranes can present several challenges, such as identifying unseen leaks, ensuring membrane compatibility with substrates, and working in various environmental conditions. Overcoming these challenges requires thorough training and familiarity with industry standards.

- Unseen leaks can be difficult to detect.

- Compatibility with substrates must be verified.

- Environmental conditions affect inspection outcomes.

How to Use This Waterproofing Membrane Inspection Checklist

- Prepare by reviewing the project specifications and waterproofing standards relevant to the membrane used.

- Conduct a preliminary inspection of the substrate to ensure it is clean, dry, and properly prepared for membrane application.

- Use the checklist during the membrane application to verify each step is performed correctly.

- Post-application, inspect the membrane thoroughly for adhesion, coverage, and any visible defects.

- Document any findings and ensure corrective actions are taken for any non-conformance observed during the inspection.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Waterproofing Membrane Inspection Checklist

- Download PDF - Waterproofing Membrane Inspection Checklist

- View Image - Waterproofing Membrane Inspection Checklist