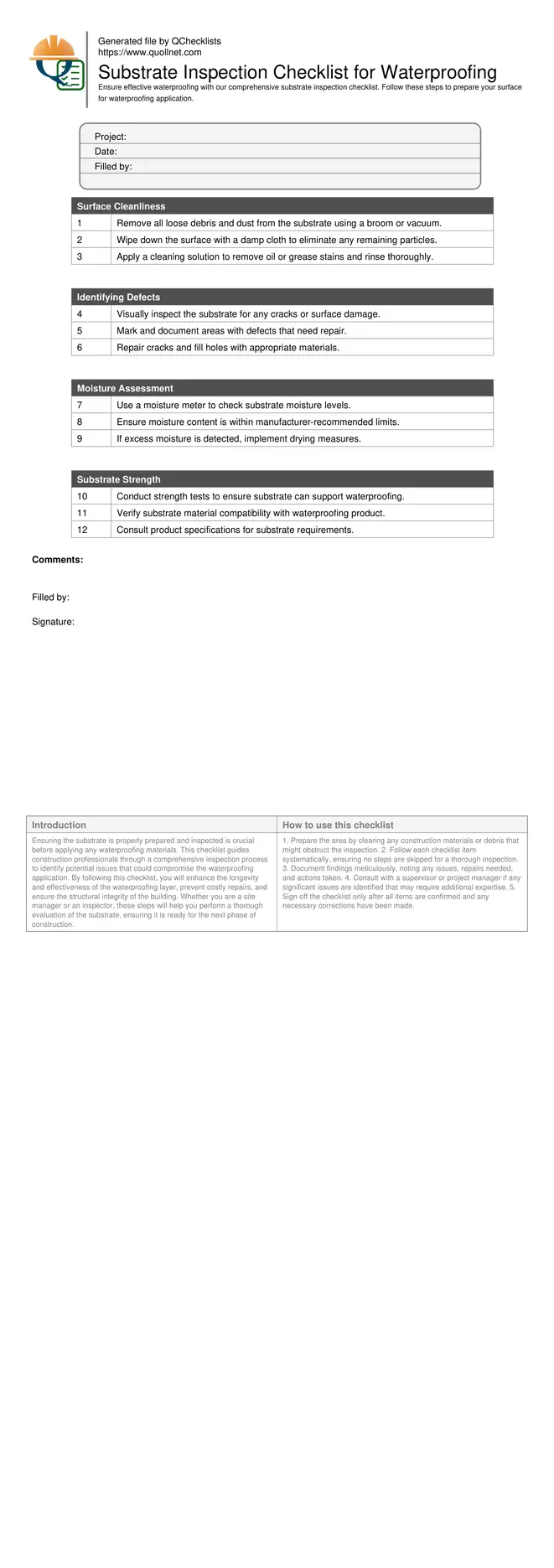

Comprehensive Checklist for Substrate Inspection Before Waterproofing

Ensuring the substrate is properly prepared and inspected is crucial before applying any waterproofing materials. This checklist guides construction professionals through a comprehensive inspection process to identify potential issues that could compromise the waterproofing application. By following this checklist, you will enhance the longevity and effectiveness of the waterproofing layer, prevent costly repairs, and ensure the structural integrity of the building. Whether you are a site manager or an inspector, these steps will help you perform a thorough evaluation of the substrate, ensuring it is ready for the next phase of construction.

- Ensure substrate is clean and free from debris to promote effective waterproofing adhesion.

- Identify cracks and surface defects early to prevent waterproofing failure.

- Verify moisture levels to avoid improper waterproofing application.

- Assess substrate strength to support the waterproofing system adequately.

- Confirm compatibility of substrate materials with waterproofing products.

Surface Cleanliness

Identifying Defects

Moisture Assessment

Substrate Strength

Importance of Substrate Cleanliness

A clean substrate is vital for the adhesion of waterproofing materials. Contaminants like dust, oil, and debris can prevent the proper bonding of waterproofing membranes, leading to potential failures. Cleaning the substrate thoroughly ensures that the membrane adheres well, providing a robust and long-lasting waterproof barrier.

- Remove all surface dust and debris.

- Check for and eliminate any oil or grease stains.

- Use appropriate cleaning agents for different contaminants.

Identifying Surface Defects

Surface defects such as cracks, holes, and uneven areas can compromise the waterproofing layer's effectiveness. Identifying and rectifying these issues before applying the waterproofing material ensures a smooth, continuous application, reducing the risk of leaks.

- Inspect for visible cracks and repair them.

- Check for holes and fill them appropriately.

- Ensure the surface is level and smooth.

Assessing Moisture Levels

Excessive moisture in the substrate can lead to poor waterproofing adhesion and potential failure. It is crucial to measure and manage moisture levels before application. Using the right tools and techniques will help ensure that the substrate is dry and ready for waterproofing.

- Use a moisture meter to assess substrate moisture.

- Ensure moisture levels are within acceptable limits.

- Take corrective measures if moisture is detected.

Substrate Strength and Compatibility

The substrate must be strong enough to support the waterproofing system. Furthermore, compatibility between the substrate material and the waterproofing product is essential to prevent chemical reactions that could degrade the waterproofing layer.

- Conduct strength tests on the substrate.

- Verify compatibility with the waterproofing material.

- Consult manufacturer guidelines for compatibility checks.

How to Use the Substrate Inspection Checklist

- Prepare the area by clearing any construction materials or debris that might obstruct the inspection.

- Follow each checklist item systematically, ensuring no steps are skipped for a thorough inspection.

- Document findings meticulously, noting any issues, repairs needed, and actions taken.

- Consult with a supervisor or project manager if any significant issues are identified that may require additional expertise.

- Sign off the checklist only after all items are confirmed and any necessary corrections have been made.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Substrate Inspection Checklist for Waterproofing

- Download PDF - Substrate Inspection Checklist for Waterproofing

- View Image - Substrate Inspection Checklist for Waterproofing