Steel Material and Fabrication Inspection Checklist

Ensuring the quality and safety of steel materials and their fabrication is crucial before erection in any construction project. This comprehensive checklist provides detailed steps to assess the integrity, compliance, and suitability of steel components. By following this guide, inspectors and construction professionals can identify potential issues early, ensure adherence to industry standards, and ultimately contribute to the longevity and safety of the structure being erected.

- Ensure all steel materials meet industry standards for quality and safety, reducing the risk of structural failure.

- Identify fabrication defects early, allowing for timely corrections before erection, saving time and costs.

- Facilitate compliance with construction regulations, ensuring all steel components are approved for use.

- Promote a safer work environment by verifying steel integrity before it is erected, minimizing accidents.

- Streamline inspection processes with a clear, actionable checklist, enhancing efficiency and thoroughness.

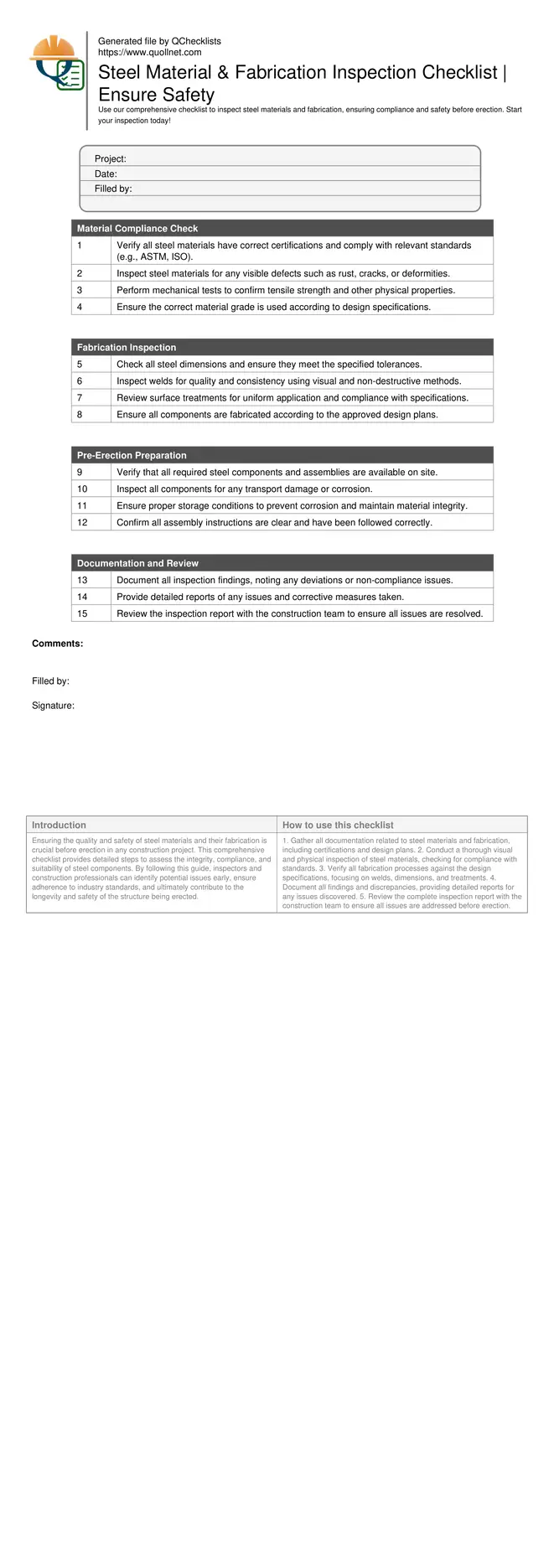

Material Compliance Check

Fabrication Inspection

Pre-Erection Preparation

Documentation and Review

Understanding Steel Material Standards

Steel materials used in construction must adhere to specific standards such as ASTM or ISO to ensure structural integrity and safety. It's essential to verify that all steel components meet these criteria before proceeding with fabrication and erection. This involves checking material certifications, conducting visual inspections, and performing tests to evaluate mechanical properties.

- Verify compliance with ASTM or ISO standards.

- Check documentation and certifications.

- Conduct visual inspections for obvious defects.

- Test mechanical properties like tensile strength.

- Ensure correct material grade is used.

Evaluating Fabrication Processes

Fabrication processes need rigorous inspection to ensure each steel component is manufactured to specification. This includes checking dimensions, weld quality, and surface treatments. Detecting fabrication errors early can prevent costly delays and enhance the structural performance of the final assembly.

- Check dimensions and tolerances.

- Inspect weld quality and consistency.

- Review surface treatments for uniformity.

- Ensure compliance with design specifications.

- Document any deviations from plans.

Preparing for Erection

Before erection, it's critical to ensure that all steel components are prepared and any potential issues are resolved. This includes verifying the availability of all necessary assemblies, confirming that all parts are free from damage, and ensuring proper storage conditions to prevent corrosion.

- Confirm availability of all components.

- Inspect for damage or corrosion.

- Ensure proper storage conditions.

- Verify all assembly instructions are followed.

- Review and approve final assembly plans.

How to Use the Steel Inspection Checklist

- Gather all documentation related to steel materials and fabrication, including certifications and design plans.

- Conduct a thorough visual and physical inspection of steel materials, checking for compliance with standards.

- Verify all fabrication processes against the design specifications, focusing on welds, dimensions, and treatments.

- Document all findings and discrepancies, providing detailed reports for any issues discovered.

- Review the complete inspection report with the construction team to ensure all issues are addressed before erection.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Steel Materials and Fabrication Inspection Checklist

- Download PDF - Steel Materials and Fabrication Inspection Checklist

- View Image - Steel Materials and Fabrication Inspection Checklist