Steel Inspection Before Erection

Inspecting steel materials and fabrication before erection is critical to ensuring the safety, integrity, and longevity of a construction project. This checklist provides a detailed guide for professionals to systematically evaluate steel components and fabrication processes before they are erected. By following this checklist, inspectors can identify and address potential issues early, ensuring compliance with industry standards and preventing costly reworks or safety hazards.

- Ensure compliance with industry standards by thoroughly inspecting steel materials and fabrication before erection.

- Identify potential defects or issues early to prevent costly reworks and enhance project safety.

- Improve project quality and longevity by verifying the integrity and specifications of steel components.

- Facilitate efficient project management through a structured, comprehensive inspection process.

- Enhance communication and documentation with clear, actionable inspection tasks.

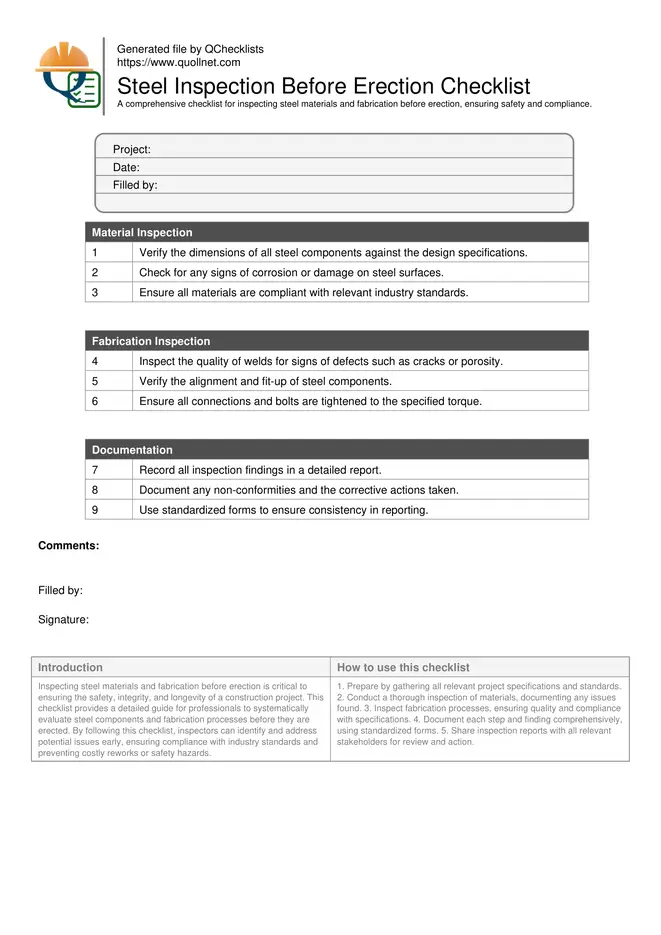

Material Inspection

Fabrication Inspection

Documentation

Importance of Steel Material Inspection

Inspecting steel materials before erection is crucial to ensure that they meet the specific requirements of the project. The inspection includes verifying the quality, dimensions, and specifications of steel materials. This process helps in identifying defects such as corrosion, cracks, or incorrect dimensions that could compromise the structure's integrity.

- Verify steel material dimensions and specifications.

- Check for visible defects like corrosion or cracks.

- Ensure compliance with relevant standards and codes.

- Document findings and prepare reports for stakeholders.

Fabrication Inspection Essentials

Fabrication inspection involves checking the process of preparing steel components for erection. This includes verifying weld quality, alignment, and connections. A thorough inspection ensures that all fabrication processes comply with design specifications and industry standards, reducing the risk of structural failures.

- Inspect weld quality and integrity.

- Verify alignment and connections.

- Check fabrication against design specifications.

- Ensure adherence to safety standards.

Documentation and Record Keeping

Proper documentation is a vital part of the inspection process. It involves maintaining detailed records of inspections, findings, and corrective actions. This documentation facilitates communication among project stakeholders and serves as a reference for future inspections or audits.

- Maintain detailed inspection records.

- Document non-conformities and actions taken.

- Use standardized forms for consistency.

- Share findings with relevant stakeholders.

How to Use This Checklist

- Prepare by gathering all relevant project specifications and standards.

- Conduct a thorough inspection of materials, documenting any issues found.

- Inspect fabrication processes, ensuring quality and compliance with specifications.

- Document each step and finding comprehensively, using standardized forms.

- Share inspection reports with all relevant stakeholders for review and action.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Steel Inspection Before Erection Checklist

- Download PDF - Steel Inspection Before Erection Checklist

- View Image - Steel Inspection Before Erection Checklist