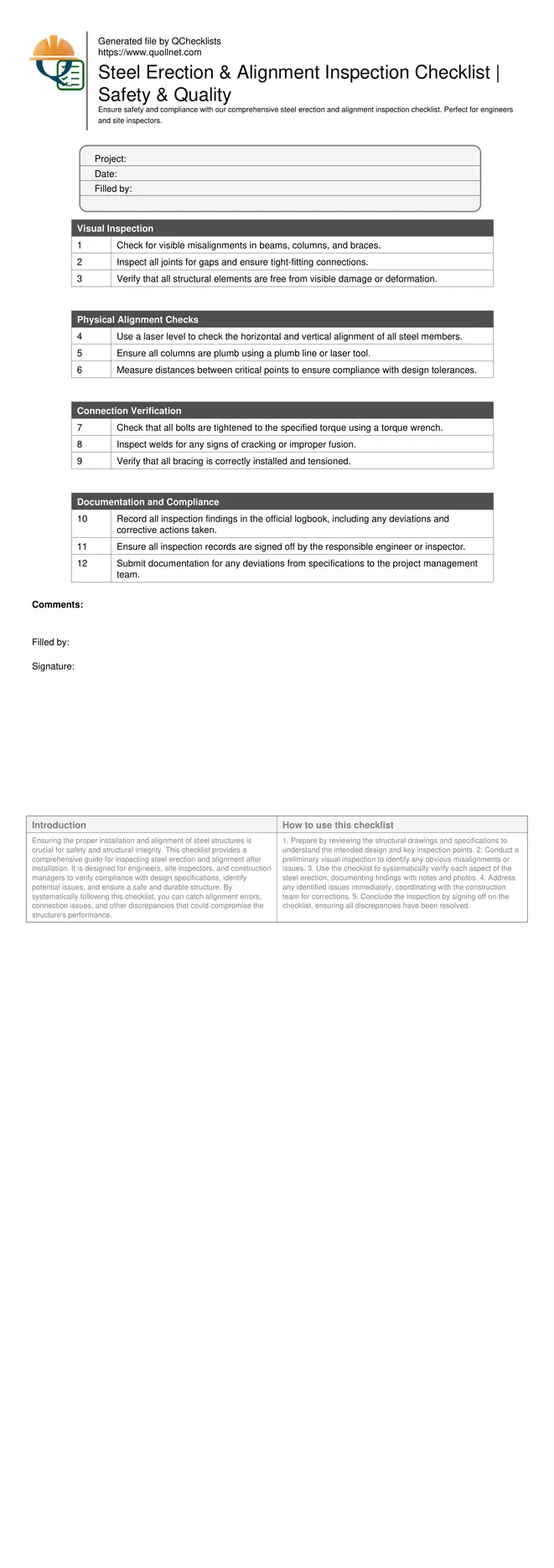

Steel Erection and Alignment Inspection Checklist

Ensuring the proper installation and alignment of steel structures is crucial for safety and structural integrity. This checklist provides a comprehensive guide for inspecting steel erection and alignment after installation. It is designed for engineers, site inspectors, and construction managers to verify compliance with design specifications, identify potential issues, and ensure a safe and durable structure. By systematically following this checklist, you can catch alignment errors, connection issues, and other discrepancies that could compromise the structure's performance.

- Verify structural integrity by checking for misalignments and ensuring all connections are secure.

- Ensure compliance with design specifications to prevent costly rework and enhance safety.

- Minimize risks by identifying potential issues early, ensuring a safe construction environment.

- Facilitate efficient inspections with a detailed, step-by-step checklist tailored for steel structures.

Visual Inspection

Physical Alignment Checks

Connection Verification

Documentation and Compliance

Importance of Steel Alignment

Proper alignment in steel erection is critical for both safety and functionality. Misaligned structures can lead to increased stress on joints, potential failure points, and safety hazards. This checklist helps ensure that all components are installed correctly, in line with engineering specifications and safety standards. By addressing alignment issues promptly, construction professionals can prevent future complications and costly repairs.

- Misalignment can lead to structural failures.

- Alignment ensures load is evenly distributed.

- Proper alignment enhances the longevity of the structure.

- Early detection of errors prevents costly rework.

Common Steel Erection Issues

Steel erection involves numerous potential pitfalls, including improper bolt installations, inadequate welding, and incorrect member placements. This checklist covers all critical inspection points to safeguard against these common issues. Ensuring that bolts are tightened to the correct torque, welds meet strength requirements, and members are placed according to design are essential steps for a successful inspection.

- Loose bolts can cause instability.

- Welding defects can compromise strength.

- Incorrect member placement affects load distribution.

- Regular inspections prevent cumulative errors.

How to Use the Steel Erection Inspection Checklist

- Prepare by reviewing the structural drawings and specifications to understand the intended design and key inspection points.

- Conduct a preliminary visual inspection to identify any obvious misalignments or issues.

- Use the checklist to systematically verify each aspect of the steel erection, documenting findings with notes and photos.

- Address any identified issues immediately, coordinating with the construction team for corrections.

- Conclude the inspection by signing off on the checklist, ensuring all discrepancies have been resolved.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Steel Erection and Alignment Inspection Checklist

- Download PDF - Steel Erection and Alignment Inspection Checklist

- View Image - Steel Erection and Alignment Inspection Checklist