Elevator Pit and Machine Room Inspection Guide

This checklist is designed for professionals tasked with inspecting elevator pits and machine rooms prior to equipment installation. It ensures that all necessary preparations, safety checks, and compliance measures are thoroughly addressed. By following this comprehensive guide, inspectors can identify potential issues that could delay installation or pose safety risks. Regular use of this checklist helps maintain high standards of safety, operational efficiency, and regulatory compliance.

- Ensure safety by identifying hazards early, preventing potential accidents during installation.

- Streamline the installation process by verifying that all prerequisites are met before equipment arrival.

- Maintain compliance with industry standards and regulations, reducing the risk of costly fines.

- Enhance operational efficiency by addressing issues that could cause delays in the elevator installation process.

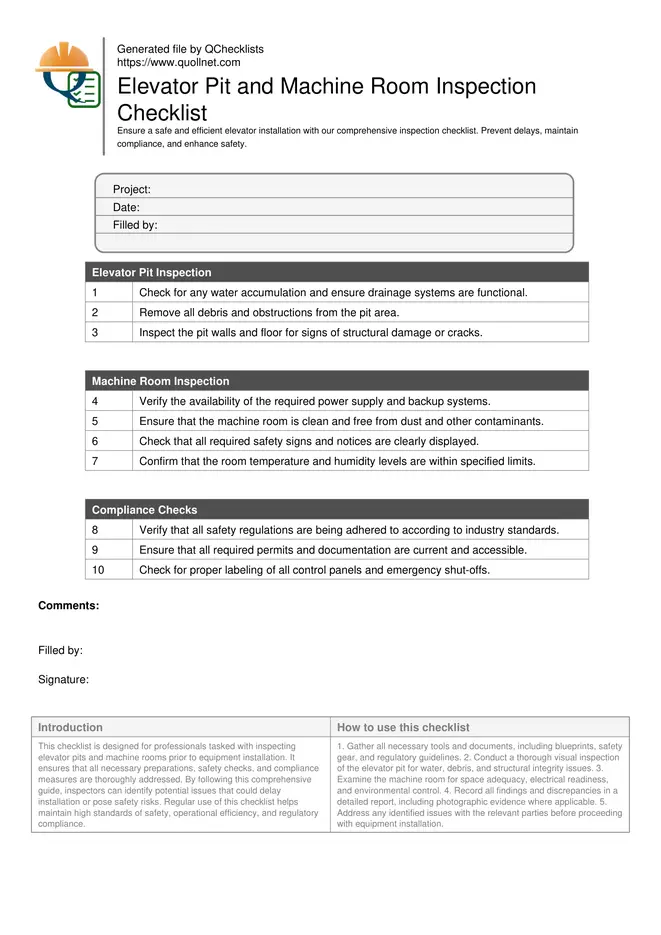

Elevator Pit Inspection

Machine Room Inspection

Compliance Checks

Importance of Pre-Installation Inspections

Pre-installation inspections of elevator pits and machine rooms are crucial for ensuring a safe and efficient installation process. These inspections help identify any structural or environmental issues that could interfere with the proper functioning of the elevator system. By proactively addressing these issues, installers can prevent costly repairs and safety hazards.

- Identify structural deficiencies early.

- Ensure compliance with safety regulations.

- Prevent delays in the installation process.

Common Issues in Elevator Pits

Elevator pits are prone to certain common issues that can affect the installation and operation of the elevator. Water accumulation, debris, and structural damage are frequent problems that need addressing. Inspectors should ensure that pits are dry, clean, and structurally sound to support the new equipment.

- Check for water accumulation.

- Ensure the pit is free of debris.

- Verify structural integrity.

Machine Room Readiness

The machine room must be prepared to accommodate the elevator's mechanical and electrical components. Adequate space, power supply, and environmental conditions are essential for the equipment's optimal performance. Inspectors should verify that all required conditions are met to prevent installation and operational issues.

- Ensure sufficient space for equipment.

- Verify power supply and electrical connections.

- Check environmental conditions (temperature, humidity).

How to Use the Elevator Inspection Checklist

- Gather all necessary tools and documents, including blueprints, safety gear, and regulatory guidelines.

- Conduct a thorough visual inspection of the elevator pit for water, debris, and structural integrity issues.

- Examine the machine room for space adequacy, electrical readiness, and environmental control.

- Record all findings and discrepancies in a detailed report, including photographic evidence where applicable.

- Address any identified issues with the relevant parties before proceeding with equipment installation.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Elevator Pit and Machine Room Inspection Checklist

- Download PDF - Elevator Pit and Machine Room Inspection Checklist

- View Image - Elevator Pit and Machine Room Inspection Checklist