Comprehensive Conveying Equipment Inspection Guide

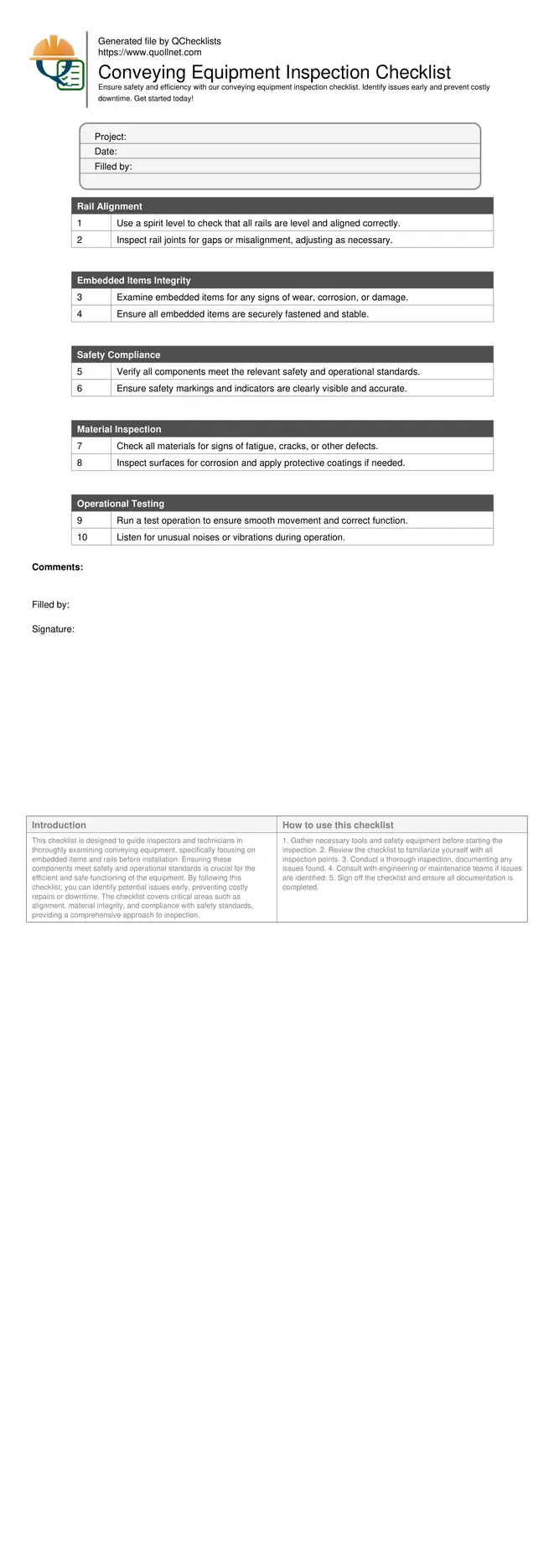

This checklist is designed to guide inspectors and technicians in thoroughly examining conveying equipment, specifically focusing on embedded items and rails before installation. Ensuring these components meet safety and operational standards is crucial for the efficient and safe functioning of the equipment. By following this checklist, you can identify potential issues early, preventing costly repairs or downtime. The checklist covers critical areas such as alignment, material integrity, and compliance with safety standards, providing a comprehensive approach to inspection.

- Ensure alignment: Proper alignment of rails and embedded items is crucial for smooth operation.

- Check material integrity: Inspect for any signs of wear or damage to prevent future failures.

- Verify safety compliance: Ensure all components meet relevant safety standards and regulations.

- Prevent downtime: Early identification of issues can avoid costly repairs and operational delays.

- Improve efficiency: A thorough inspection enhances the overall efficiency of the conveying system.

Rail Alignment

Embedded Items Integrity

Safety Compliance

Material Inspection

Operational Testing

Importance of Pre-Installation Inspections

Pre-installation inspections of conveying equipment are vital to ensure all components are in optimal condition and properly aligned. This step is crucial in preventing future operational issues and ensuring the safety of workers. Neglecting this can lead to accidents, increased maintenance costs, and system inefficiencies.

- Identify potential issues before they escalate.

- Ensure compliance with safety standards.

- Reduce the risk of costly downtime.

Key Inspection Points

When inspecting conveying equipment, focus on several key areas. Check the alignment of rails, examine the condition of embedded items, and verify that all components meet the necessary specifications. Each of these aspects plays a critical role in the smooth operation of the equipment.

- Verify rail alignment and levelness.

- Inspect embedded items for damage or wear.

- Check compliance with manufacturer specifications.

Common Issues and How to Address Them

During inspections, common issues such as misalignment, corrosion, and material fatigue may be encountered. Addressing these issues promptly can prevent system failures. Use appropriate tools and techniques to rectify any identified problems.

- Misalignment can lead to operational inefficiencies.

- Corrosion must be addressed to prevent structural failures.

- Regular maintenance can mitigate material fatigue.

How to Use the Conveying Equipment Inspection Checklist

- Gather necessary tools and safety equipment before starting the inspection.

- Review the checklist to familiarize yourself with all inspection points.

- Conduct a thorough inspection, documenting any issues found.

- Consult with engineering or maintenance teams if issues are identified.

- Sign off the checklist and ensure all documentation is completed.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Conveying Equipment Inspection Checklist

- Download PDF - Conveying Equipment Inspection Checklist

- View Image - Conveying Equipment Inspection Checklist