Inspecting Concrete Placement and Consolidation

This checklist is designed to guide professionals in inspecting concrete placement and consolidation during the pouring process. Ensuring the correct placement and consolidation of concrete is critical to the structural integrity and longevity of any concrete structure. This checklist provides a comprehensive series of tasks that help in maintaining the quality of concrete work, reduce worksite errors, and enhance safety. By following these detailed steps, inspectors can verify that all relevant standards are being met, ensuring that the concrete sets properly and achieves its designed strength.

- Ensure structural integrity: This checklist helps verify proper placement and consolidation of concrete, crucial for structural strength.

- Enhance worksite safety: Following these guidelines reduces the risk of structural failures and associated safety hazards.

- Maintain quality standards: It ensures compliance with industry standards for concrete work, improving overall project quality.

- Optimize resource use: Efficient inspection processes minimize material waste and labor costs.

- Improve longevity: Proper inspection leads to concrete structures that meet longevity expectations by avoiding premature failures.

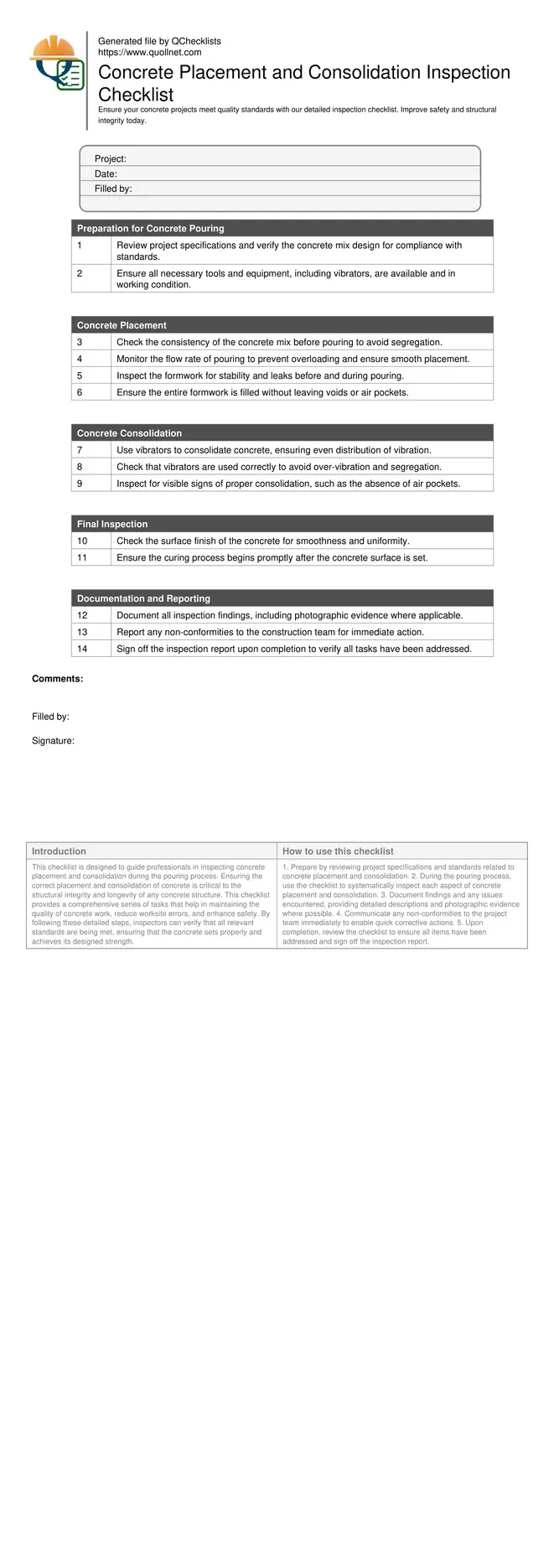

Preparation for Concrete Pouring

Concrete Placement

Concrete Consolidation

Final Inspection

Documentation and Reporting

The Importance of Proper Concrete Placement

Proper concrete placement is essential to ensure that the structure achieves its intended strength and durability. During the pouring process, it is vital to follow precise methods to avoid segregation and ensure a uniform material throughout the structure. Inspectors must monitor the flow and placement techniques to prevent common issues like air pockets and cold joints.

- Monitor concrete flow to prevent segregation.

- Ensure uniform placement to avoid structural weaknesses.

- Inspect for air pockets and address immediately.

- Prevent cold joints by continuous pouring.

- Verify concrete mix consistency before placement.

Critical Aspects of Concrete Consolidation

Concrete consolidation involves the removal of entrapped air and the compaction of the mix to ensure maximum density and strength. This process requires careful attention to detail, particularly the use of the right equipment and techniques. Vibrators are typically used to achieve this, and inspectors must ensure they are operated correctly to avoid over-vibration, which can cause segregation.

- Use vibrators to remove air and compact concrete.

- Avoid over-vibration to prevent segregation.

- Inspect equipment for proper functionality.

- Ensure even distribution of vibration.

- Check for visible signs of proper consolidation.

How to Use the Concrete Inspection Checklist

- Prepare by reviewing project specifications and standards related to concrete placement and consolidation.

- During the pouring process, use the checklist to systematically inspect each aspect of concrete placement and consolidation.

- Document findings and any issues encountered, providing detailed descriptions and photographic evidence where possible.

- Communicate any non-conformities to the project team immediately to enable quick corrective actions.

- Upon completion, review the checklist to ensure all items have been addressed and sign off the inspection report.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Concrete Placement and Consolidation Inspection Checklist

- Download PDF - Concrete Placement and Consolidation Inspection Checklist

- View Image - Concrete Placement and Consolidation Inspection Checklist