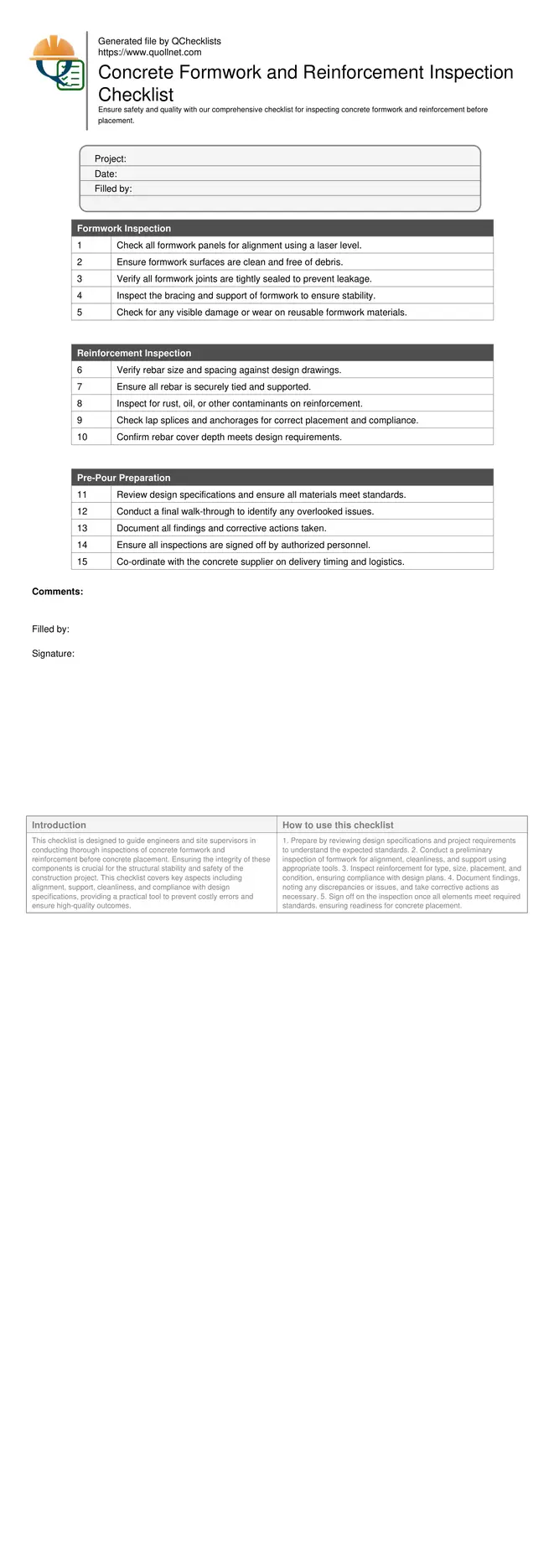

Concrete Formwork and Reinforcement Inspection

This checklist is designed to guide engineers and site supervisors in conducting thorough inspections of concrete formwork and reinforcement before concrete placement. Ensuring the integrity of these components is crucial for the structural stability and safety of the construction project. This checklist covers key aspects including alignment, support, cleanliness, and compliance with design specifications, providing a practical tool to prevent costly errors and ensure high-quality outcomes.

- Guarantees structural integrity by ensuring formwork and reinforcement meet design specifications.

- Helps prevent costly errors and delays by identifying issues before concrete placement.

- Promotes safety by ensuring proper support and alignment of formwork and reinforcement.

- Enhances quality control through systematic inspection and documentation.

- Facilitates compliance with industry standards and regulations.

Formwork Inspection

Reinforcement Inspection

Pre-Pour Preparation

Importance of Formwork Inspection

Formwork serves as a temporary mold for concrete, which must withstand various pressures during the curing process. Inspecting formwork involves checking for alignment, cleanliness, and adequate support to prevent deformation or collapse. Proper inspection ensures that the concrete pour proceeds smoothly and that the final structure is dimensionally accurate and stable.

- Check alignment using a laser level or plumb bob.

- Ensure all formwork is clean and free of debris.

- Verify proper support and bracing to prevent movement.

- Inspect for damage or wear in reusable formwork.

- Confirm compliance with design specifications.

Reinforcement Inspection Essentials

Reinforcement is critical for adding tensile strength to concrete. Inspecting reinforcement involves verifying the type, size, and placement of rebar against design plans, ensuring that all components are securely tied and free of rust or contamination. These checks are vital for maintaining the structural integrity and safety of the concrete structure.

- Verify rebar size and spacing match design specifications.

- Ensure all reinforcement is properly tied and supported.

- Inspect for rust, oil, or other contaminants on rebar.

- Check lap splices and anchorage for compliance.

- Confirm cover depth meets design requirements.

Using the Concrete Inspection Checklist

- Prepare by reviewing design specifications and project requirements to understand the expected standards.

- Conduct a preliminary inspection of formwork for alignment, cleanliness, and support using appropriate tools.

- Inspect reinforcement for type, size, placement, and condition, ensuring compliance with design plans.

- Document findings, noting any discrepancies or issues, and take corrective actions as necessary.

- Sign off on the inspection once all elements meet required standards, ensuring readiness for concrete placement.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Concrete Formwork and Reinforcement Inspection Checklist

- Download PDF - Concrete Formwork and Reinforcement Inspection Checklist

- View Image - Concrete Formwork and Reinforcement Inspection Checklist