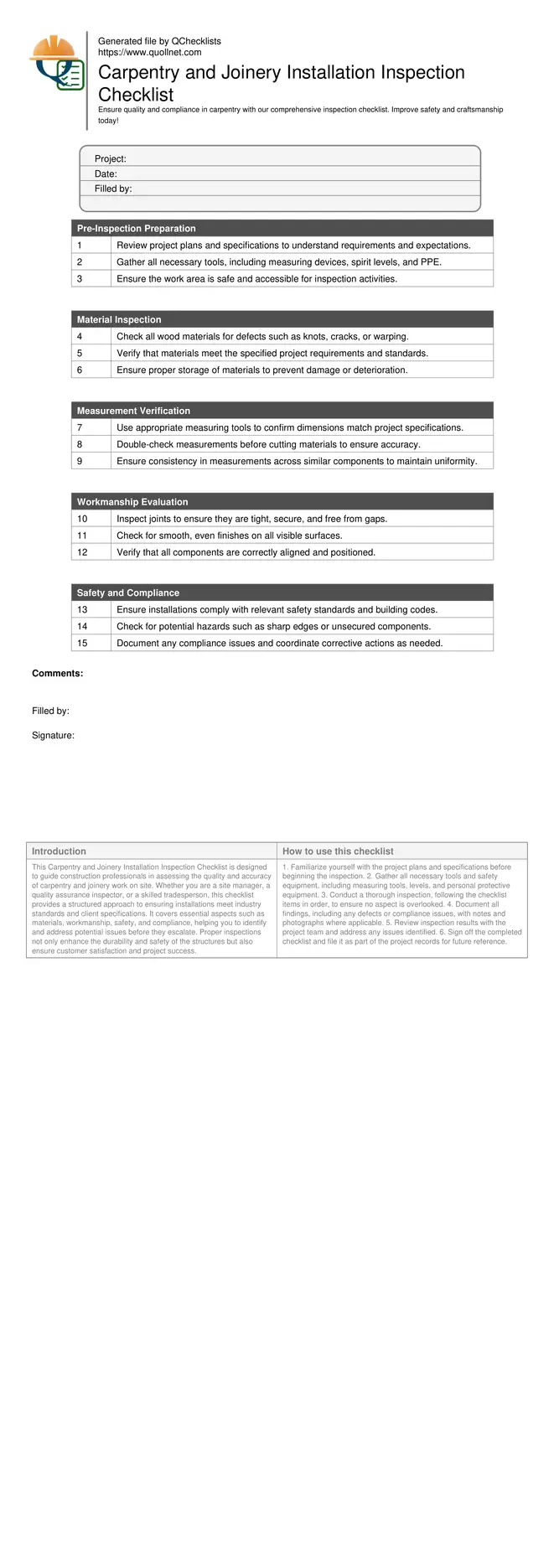

Carpentry and Joinery Installation Inspection

This Carpentry and Joinery Installation Inspection Checklist is designed to guide construction professionals in assessing the quality and accuracy of carpentry and joinery work on site. Whether you are a site manager, a quality assurance inspector, or a skilled tradesperson, this checklist provides a structured approach to ensuring installations meet industry standards and client specifications. It covers essential aspects such as materials, workmanship, safety, and compliance, helping you to identify and address potential issues before they escalate. Proper inspections not only enhance the durability and safety of the structures but also ensure customer satisfaction and project success.

- Ensure accuracy and quality of carpentry installations with step-by-step checks.

- Identify potential issues early to prevent costly repairs and project delays.

- Verify compliance with industry standards and client specifications.

- Improve safety by ensuring installations are secure and stable.

- Enhance client satisfaction by delivering high-quality craftsmanship.

Pre-Inspection Preparation

Material Inspection

Measurement Verification

Workmanship Evaluation

Safety and Compliance

Importance of Accurate Measurements

Accurate measurements are crucial in carpentry and joinery to ensure that all elements fit together correctly and function as intended. Errors in measurement can lead to structural weaknesses, misalignments, and aesthetic issues. This section emphasizes the need for precision in measuring and cutting materials, as well as the benefits of using the right tools for the job.

- Use calibrated measuring tools for precision.

- Double-check measurements before cutting.

- Ensure all elements align correctly during installation.

- Check for consistency in measurements across similar components.

- Address any discrepancies immediately to prevent cumulative errors.

Evaluating Material Quality

The quality of materials used in carpentry and joinery greatly affects the durability and appearance of the finished product. Inspectors must verify that materials meet specified standards and are free from defects such as warping, cracking, or knots that could compromise their integrity.

- Inspect materials for visible defects before use.

- Verify that materials meet project specifications.

- Ensure proper storage to prevent damage or deterioration.

- Check for uniformity in wood grain and color.

- Use appropriate materials for specific environmental conditions.

Workmanship and Craftsmanship

Workmanship is a critical component of carpentry and joinery that affects both the functionality and aesthetics of installations. Inspecting the quality of workmanship involves checking the precision of cuts, the accuracy of joints, and the smoothness of finishes.

- Ensure joints are tight and secure.

- Check for smooth, even finishes on surfaces.

- Verify that all components are correctly aligned.

- Inspect the quality of fasteners and adhesives used.

- Look for any signs of poor workmanship such as gaps or rough edges.

Safety and Compliance Checks

Safety and compliance are paramount in any construction project. This section provides guidance on ensuring that carpentry and joinery installations adhere to safety regulations and industry standards. Proper inspections can prevent accidents and ensure the longevity of the structure.

- Verify compliance with relevant safety standards and codes.

- Ensure all installations are stable and secure.

- Check for potential hazards such as sharp edges or unsecured components.

- Ensure proper use of personal protective equipment (PPE) during inspections.

- Document compliance issues and coordinate corrective actions promptly.

How to Use the Carpentry and Joinery Inspection Checklist

- Familiarize yourself with the project plans and specifications before beginning the inspection.

- Gather all necessary tools and safety equipment, including measuring tools, levels, and personal protective equipment.

- Conduct a thorough inspection, following the checklist items in order, to ensure no aspect is overlooked.

- Document all findings, including any defects or compliance issues, with notes and photographs where applicable.

- Review inspection results with the project team and address any issues identified.

- Sign off the completed checklist and file it as part of the project records for future reference.

Call to Action

-

Start Interactive Checklist

Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Carpentry and Joinery Installation Inspection Checklist

- Download PDF - Carpentry and Joinery Installation Inspection Checklist

- View Image - Carpentry and Joinery Installation Inspection Checklist